What We Offer

At Croell, Inc., we deliver concrete solutions for every scale of construction — from a few yards for a backyard slab to thousands for warehouses, feedlots, wind farms, and even large-scale data centers. Whether your project is residential, commercial, agricultural, or industrial, our team has the expertise, equipment, and proven experience to get it done.

With 20+ wind farm projects, multiple data centers, and countless paving and bridge jobs behind us, we bring capability you can count on. And when there isn’t a plant nearby, our portable operations can bring the plant directly to your jobsite — ensuring you get the concrete you need, wherever the work takes you.

What sets us apart is more than our scale. Customers know us for dependable service, responsive scheduling, and managers who go the extra mile to keep trucks moving and pours on track. Whether it’s a last-minute order or a complex, multi-phase project, we find a way to meet your schedule safely and efficiently.

Partner with Croell, Inc. for concrete solutions built around your goals — backed by proven capability and delivered with the personal service that has defined us for generations.

With 20+ wind farm projects, multiple data centers, and countless paving and bridge jobs behind us, we bring capability you can count on. And when there isn’t a plant nearby, our portable operations can bring the plant directly to your jobsite — ensuring you get the concrete you need, wherever the work takes you.

What sets us apart is more than our scale. Customers know us for dependable service, responsive scheduling, and managers who go the extra mile to keep trucks moving and pours on track. Whether it’s a last-minute order or a complex, multi-phase project, we find a way to meet your schedule safely and efficiently.

Partner with Croell, Inc. for concrete solutions built around your goals — backed by proven capability and delivered with the personal service that has defined us for generations.

“We have been with Croell, Inc. for a long time. They have treated us great. Even for last minute orders, they do everything they can to get us concrete in a timely manner. Managers do a good job helping on big pours to get trucks in and out.”

Matt Nolt, Owner

Nolts Custom Concrete LLC

Nolts Custom Concrete LLC

“Wicks Construction and Croell Ready Mix have worked together since their inceptions in the 1960s. As a 3rd generation owner, I always look forward to working with Croell as they continue to grow and supply Wicks Construction crews with Ready Mix across the Upper Midwest. I enjoy the working alongside Croell’s management team; from quantities and quotes to their quality control and safety. I know I can depend on them to supply us with the correct information as well as be a resource when needed. Our guys in the field most enjoy working with Croell as they are able to schedule directly with the plant and regional managers. They always find a way to meet our schedule, production and supply quality Ready Mix concrete safely.”

Gavin Wicks, Vice-President

Wicks Construction, Inc.

Wicks Construction, Inc.

“Croell has been one of our top concrete Redi Mix Plants we like to work close with here in Iowa. As a concrete company we can ensure a good product to our customers as they are also reliable for being there to help us get the job done in a timely manner. When there is a big job that needs done, the managers are great at coordinating to keep the concrete trucks moving in.”

Shannon Hoover, Co-Owner

JED Construction

JED Construction

Join countless others who have experienced the difference with Croell, Inc.

Contact us today to see how we can help you achieve your goals.

Contact us today to see how we can help you achieve your goals.

DIY FAQs

Got questions? We've got answers! Here are some of the most common inquiries we receive about Croell, Inc. and our services:

Concrete is a material made primarily from cement, aggregates (rock and sand), and water. Concrete dates back more than 5,000 years and is the most widely used man-made product in the world.

Many people believe cement and concrete are interchangeable terms, but cement is actually an ingredient used in making concrete. You can learn more about concrete from this video from the Concrete Network.

Ready mix is an unhardened, fluid form of concrete that is delivered in a concrete truck that agitates and mixes the concrete on the way to the job.

Ready mix concrete is a type of concrete that is mixed at a plant and delivered to a jobsite or construction site. Redi-mix concrete is a type of concrete that is typically mixed on-site for smaller applications.

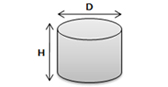

Concrete is measured in cubic yards (areas 3’ x 3’ x 3’). You can use our concrete calculator on this page to measure how much concrete you will need. It’s incredibly important that you measure accurately and order enough concrete. It’s a good idea to order a little more than you think you’ll need.

Slump measures the consistency of a batch of fresh concrete. It refers to the ease with which the concrete flows, thus indicating the workability of the concrete. Different types of jobs require different slump ratings. Slump testing is used on-site to ensure uniform consistency between individual batches of concrete.

The materials available for concrete mix design vary by location. Because of this, price also varies by location. Contact your nearest Croell ready mix facility for an estimate.

Concrete will not set on its own at temperatures under 35 degrees. While heated water and aggregates or the use of accelerants do allow concrete to be poured at temperatures below freezing, it is more costly. High temperatures above 90 degrees can make concrete set faster than recommended, reducing the strength of the concrete. Additives can be used to slow down this process.

One of the best ways to ensure your concrete stands the test of time is to work with a reputable ready mixed concrete producer. The Concrete Network offers tips on controlling and repairing cracks in your concrete, as well as how to clean and remove stains on concrete. In addition, it is highly recommended to always seal your concrete.

New information on www.ConcreteNetwork.com outlining the benefits of applying concrete sealer helps consumers protect newly finished concrete surfaces and provides examples of how to protect your investment. According to the site, sealing newly placed concrete can offer a host of benefits, and is the most efficient way to improve the performance and longevity of interior and exterior concrete surfaces. With different sealer options to choose from, there's no reason why any concrete surface should be without the added protection. The six benefits of using a concrete sealer include:

-

- Enriching the color intensity.

- Adding sheen to the surface.

- Blocking the penetration of dirt and chemicals.

- Inhibiting dusting of the surface.

- Preventing the intrusion of water.

- Protecting against abrasion and wear.

Concrete Driveway Reinforcement: Use rebar for structural support and synthetic fibers to control shrinkage cracks. Using steel reinforcement will provide additional structural capacity for your driveway and is especially important if the slab will be exposed to heavy traffic. Reinforcement won't prevent cracks, but it will help hold them together if they do occur. Reinforcement can be either wire mesh or ½-inch (#4) steel rebar placed in a grid pattern with a spacing between bars of approximately 12 inches. In either case, blocks should be used under the reinforcement to keep the grids centered within the concrete.

Use Fibers for Secondary Reinforcement: Fibers can be added to the concrete mix in lieu of welded wire mesh. If you could look into a section of concrete poured with fibers you would see millions of fibers distributed in all directions throughout the concrete mix. As water evaporates from the concrete (plastic shrinkage) micro cracks begin to appear. The cracks intersect with the fibers which block their growth and provide higher tensile strength capacity at this crucial time. The problem with welded wire mesh is that it often ends up on the ground from being stepped on as the concrete is being placed (particularly if no support blocks are used). Another problem is that mesh does not prevent or minimize cracking-it simply holds cracks that have already occurred together.

Use Fibers for Secondary Reinforcement: Fibers can be added to the concrete mix in lieu of welded wire mesh. If you could look into a section of concrete poured with fibers you would see millions of fibers distributed in all directions throughout the concrete mix. As water evaporates from the concrete (plastic shrinkage) micro cracks begin to appear. The cracks intersect with the fibers which block their growth and provide higher tensile strength capacity at this crucial time. The problem with welded wire mesh is that it often ends up on the ground from being stepped on as the concrete is being placed (particularly if no support blocks are used). Another problem is that mesh does not prevent or minimize cracking-it simply holds cracks that have already occurred together.

Air entrainment is particularly effective in providing resistance to freeze-thaw cycles. When the moisture in concrete freezes, these air cells relieve internal pressure by providing microscopic chambers for the expansion of water as it freezes. Some air entraining mixtures contain a catalyst for more rapid and complete hydration of Portland cement. To protect concrete from damage during freezing, bubbles must have the proper size, distribution and volume. ASTM C 260 specifies requirements for air entraining admixtures and you should be sure to mention how the concrete will be used when ordering your mix design.

- Benefits of air-entrainment include:

- Improved resistance of concrete to severe frost action or freeze/thaw cycles

- High resistance to cycles of wetting and drying

- High degree of workability

- High degree of durability

- Dosage: Typical air entrainment ranges from 5% to 8% of the volume of concrete.

Admixtures are additions to the concrete mix used to achieve certain goals. Here are the main admixtures and what they aim to achieve:

- Accelerating admixture - accelerators are added to concrete to reduce setting time of the concrete and to accelerate early strength. The amount of reduction in setting time varies depending on the amount of accelerator used (see your ready mix supplier and describe your application). Calcium chloride is a low cost accelerator, but specifications often call for a non-chloride accelerator to prevent corrosion of reinforcing steel.

- Retarding admixtures - often used in hot weather conditions to delay setting time. They are also used to delay set of more difficult jobs or for special finishing operations like exposing aggregate. Many retarders also act as a water reducer.

- Fly ash - is a by-product of coal burning plants. Fly ash can replace 15%-30% of the cement in the mix. Cement and fly ash together in the same mix make up the total cementious material.

-

-

- Fly ash improves workability

- Fly ash is easier to finish

- Fly ash reduces the heat generated by the concrete

- Fly ash costs to the amount of the cement it replaces

-

- Air entraining admixtures - must be used whenever concrete is exposed to freezing and thawing, and to deicing salts. Air entraining agents entrain microscopic air bubbles in the concrete: when the hardened concrete freezes, the frozen water inside the concrete expands into these air bubbles instead of damaging the concrete.

-

- Air entrainment improves concrete workability

- Air entrainment improves durability

- Air entrainment produces a more workable mix

-

- Water-reducing admixtures - reduce the amount of water needed in the concrete mix. The water-cement ratio will be lower and the strength will be greater. Most low-range water reducers reduce the water needed in the mix by 5% to 10%. High-range water reducers reduce the mix water needed by 12% to 30% but are very expensive and rarely used in residential work.

Concrete Calculator

Use our concrete calculator to determine how many yards are needed for your next project!

Slabs

Columns

Footings

Walls